Steel had been around for 3,000 years. But it was very labor- and energy-intensive and therefore too expensive to use for anything more than swords and shields. Then, in 1854, Henry Bessemer discovered that blowing air into molten iron rapidly converted it into steel. This led to a seven-fold increase in productivity, dramatically lowering the cost of steel. This leads us to today’s recommendation – IperionX Ltd. (IPX), advises Carl Delfeld, editor of Cabot Explorer.

Over the last century, military power came to be measured in terms of producing ships, automobiles, and airplanes, plus a broad array of technologies and the fuel to keep them moving. This meant mineral production and processing.

First, there was steel. Then, there came aluminum. Then titanium joined the list of essential metals, and the lack of domestic production is now threatening the national security of the United States.

One of the most common uses for titanium is in the aerospace industry. Its combination of high strength and relatively light weight (45% lighter than steel but stronger) make it a desirable metal for use in planes and rockets because of fuel efficiency mandates.

The marine industry is another area that frequently relies on titanium because of its corrosion resistance, especially in saltwater environments where corrosion is a concern. Many medical devices also use titanium because of its strength and corrosion resistance.

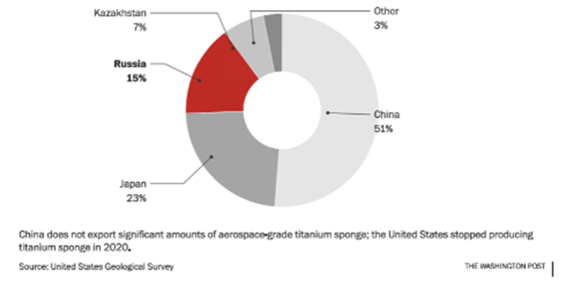

The problem right now is that two of America’s rivals, China and Russia, account for 65% of titanium supply. And that’s where IPX comes in. It aims to become a leading American titanium metal and critical materials company.

It is using patented metal technologies to produce high-performance titanium alloys, from titanium minerals or scrap titanium. And it is trying to do it at lower energy costs and lower carbon emissions. Under a regulation known as the Specialty Metals Amendment, the Defense Department is required to source titanium and titanium alloys from American sources or other qualified countries – usually NATO members or other US allies.

IperionX’s HAMR titanium furnace has passed thresholds to produce low-cost titanium, having successfully met tough factory acceptance technical tests over 18+ months of industrialized, pilot-scale production in Utah. The company also has backward integration to titanium minerals via control of the largest US titanium resource in Tennessee.

Installation and commissioning of the HAMR titanium furnace is expected during the second quarter, before producing its first titanium metal in mid-2024.

A further sign of the strategic value and credibility for IperionX is that the company has received the first $2.4 million payment from a $12.7 million Department of Defense DPA Title III grant to fund the ramp-up of its Virginia Titanium Production Facility.

Recommended Action: Buy IPX.